Overview:Product descriptionTray type continuous dryer is a highly efficient conduction type continuous drying equipment. Its unique structure and working principle determine that it has the characteristics of high thermal efficiency, low energy consumption, s…

Product description

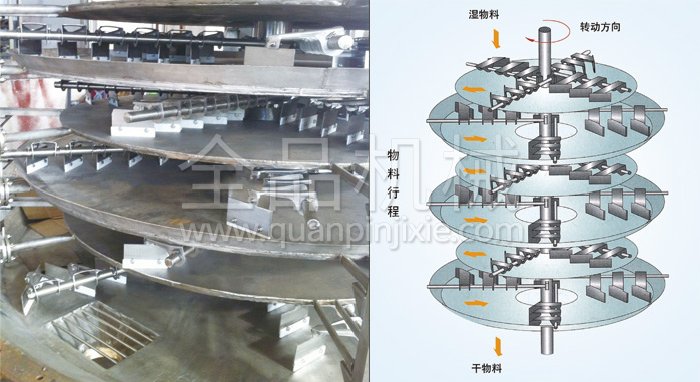

Tray type continuous dryer is a highly efficient conduction type continuous drying equipment. Its unique structure and working principle determine that it has the characteristics of high thermal efficiency, low energy consumption, small footprint, simple configuration, convenient operation and control, and good operating environment. It is widely used in chemicals, medicine, pesticides, food, feed, and agriculture. Drying operations in industries such as by-product processing. It is well received in practice in various industries. Now it produces three types of atmospheric pressure, airtight, vacuum, 1200, 1500, 2200, 3000 four types, A (carbon steel), B (stainless steel in contact with materials), C (on the basis of B, add steam pipes) The road, main shaft and bracket are made of stainless steel, and the cylinder and cover are lined with stainless steel). Three kinds of materials, a drying area of 4~180m 2, a total of hundreds of models of series products, and can provide matching auxiliary equipment, which can meet the needs of users for drying various materials.

Performance characteristics

(1) Easy regulation and strong applicability

◎By adjusting the thickness of the material layer, the rotation speed of the main shaft, the number of harrow arms, the type and size of the harrow blades, the drying process can be achieved better.

◎Each layer of the drying tray can be individually heated or cooled by heating or cooling the material through the heating or cooling medium, and the temperature control of the material is accurate and easy.

◎The residence time of materials can be adjusted accurately.

◎Single flow direction of materials, no back-mixing phenomenon, uniform drying, stable quality, no need for re-mixing.

(2) Simple and easy operation

◎The operation of driving and stopping the dryer is very simple.

◎After stopping the feed, the transporting material dirt rake leaves can quickly empty the material in the dryer.

◎Through the special sight glass of the large inspection door, the inside of the equipment can be carefully cleaned and observed.

(3) Low energy consumption

◎The material layer is very thin, the spindle speed is low, the power required by the material conveying system is small, and the power consumption is low.

◎Drying by conduction heat, high thermal efficiency and low energy consumption.

(4) The operating environment is good, the solvent can be recycled, and the dust emission meets the requirements

◎Normal pressure type: Due to the low air velocity in the equipment and the humidity distribution in the equipment, it is difficult for dust to float to the top of the equipment, so the exhaust gas from the top moisture exhaust port contains almost no dust.

◎Closed type: equipped with a solvent recovery device, which can easily recover the organic solvent in the wet gas. The solvent recovery device is simple and the recovery rate is high. For flammable, explosive, toxic and easily oxidized materials, nitrogen can be used as a moisture-carrying gas for closed-circuit circulation to make it safe to operate. It is especially suitable for drying flammable, explosive and toxic materials.

◎Vacuum type: A disc dryer operated under vacuum, especially suitable for drying heat-sensitive materials.

(5) Convenient installation and small floor space

◎The dryer leaves the factory as a whole and is transported as a whole. It only needs to be hoisted in place, making the installation and positioning very easy.

◎Due to the layered arrangement and vertical installation of the drying plate, even if the drying area is large, the floor space is small.

◎Heating medium: steam, hot water, heat-conducting oil, hot water heating at 100℃, 100℃~150℃ saturated steam or superheated steam ≤0.4MPa, 150℃~320℃ heat-conducting oil For heating, electricity, heat transfer oil, molten salt, etc. can be used when the temperature is greater than 320°C.

◎Rolling: For materials that are easy to agglomerate and need to be crushed, adding rollers at appropriate positions can enhance the heat transfer and drying process.

◎Vacuum type: cylindrical shell, the design pressure is 0.1Mpa, the main pipeline of heating medium inlet and outlet is in the shell.

Generally used in the case of large evaporation to enhance drying efficiency.

The wet material is continuously added to the drying plate on the first layer of the upper part of the dryer from the feeder, and the rake arm with rake blades rotates, so that the rake arm continuously churns the material. The material flows through the surface of the drying plate along an exponential spiral. The material on the small drying plate is moved to the outer edge. The material on the large drying plate moves inward and falls from the middle blanking port into the next layer of the small drying plate. The large and small drying trays are arranged alternately up and down, so that the material can continuously flow through the entire dryer. A heating medium is introduced into the hollow drying plate. The heating medium is in the form of saturated steam, hot water and heat-conducting oil. The heating medium enters from one end of the drying plate and exits from the other end. Dried materials fall from the last layer of the drying plate to the bottom layer of the shell, and are finally moved by the rake leaves to the discharge port for discharge. The moisture escapes from the material and is discharged through the moisture exhaust port provided on the top cover. The moisture vapor of the vacuum type disc dryer is drawn out by the vacuum pump port provided on the top cover. The dry materials discharged from the bottom layer can be directly packaged. By adding finned heater, solvent recovery condenser, bag filter, dry material backmixing mechanism, induced draft fan and other auxiliary equipment, it can improve its drying production capacity. Dry paste and heat sensitive materials can be easily recovered Solvent, and can perform pyrolysis and reaction operations.

| Specification | Outer diameter mm | Height mm | Dry area m2 | Power Kw |

| 1200/4 | Φ1850 | 2718 | 3.3 | 1 |

| 1200/6 | 3138 | 4.9 | ||

| 1200/8 | 3558 | 6.6 | 1.5 | |

| 1200/10 | 3978 | 8.2 | ||

| 1200/12 | 4398 | 9.9 | 2.2 | |

| 1500/6 | Φ2100 | 3022 | 8.0 | |

| 1500/8 | 3442 | 10.7 | ||

| 1500/10 | 3862 | 13.4 | ||

| 1500/12 | 4282 | 16.1 | 3.0 | |

| 1500/14 | 4702 | 18.8 | ||

| 1500/16 | 5122 | 21.5 | ||

| 2200/6 | Φ2900 | 3319 | 18.5 | |

| 2200/8 | 3739 | 24.6 | ||

| 2200/10 | 4159 | 30.8 | 4.0 | |

| 2200/12 | 4579 | 36.9 | ||

| 2200/14 | 4999 | 43.1 | 5.5 | |

| 2200/16 | 5419 | 19.3 | ||

| 2200/18 | 5839 | 55.4 | 7.5 | |

| 2200/20 | 6259 | 61.6 | ||

| 2200/22 | 6679 | 67.7 | 11 | |

| 2200/24 | 7099 | 73.9 | ||

| 2200/26 | 7519 | 80.0 |

| Specification | Outer diameter mm | Height mm | Dry area m2 | Power Kw |

| 2500/6 | Φ3150 | 3319 | 26.3 | 4 |

| 2500/8 | 3739 | 35 | ||

| 2500/10 | 4159 | 43.8 | 5.5 | |

| 2500/12 | 4579 | 52.5 | ||

| 2500/14 | 4999 | 61.3 | 7.5 | |

| 2500/16 | 5419 | 70 | ||

| 2500/18 | 5839 | 78.8 | 11 | |

| 2500/20 | 6259 | 87.5 | ||

| 2500/22 | 6679 | 96.3 | ||

| 2500/24 | 7099 | 105 | 13 | |

| 2500/26 | 7519 | 113.8 | ||

| 3000/8 | Φ3800 | 4050 | 48 | 11 |

| 3000/10 | 4650 | 60 | ||

| 3000/12 | 5250 | 72 | ||

| 3000/14 | 5850 | 84 | ||

| 3000/16 | 6450 | 96 | ||

| 3000/18 | 7050 | 108 | 13 | |

| 3000/20 | 7650 | 120 | ||

| 3000/22 | 8250 | 132 | ||

| 3000/24 | 8850 | 144 | ||

| 3000/26 | 9450 | 156 | 15 | |

| 3000/28 | 10050 | 168 |

1. Drying rate of drying equipment1. The weight lost by the material in unit time and unit area is called drying rate.2. Drying process(1) In…

1. At present, the enamel spray powder in my countrys glass-lined equipment industry is mainly divided into two categories: cold spray (powde…

The new type of rotary flash dryer uses a variety of devices, such as a variety of feeding devices, so that the feeding is continuous and sta…

Centrifugal spray dryer is approvedIn terms of production process and equipment performance, our spray dryer has been highly recognized and p…

Drying equipment is very widely used in industrial testing. Many fields require the use of drying equipment. Similarly, drying equipment also…

The enamel rotary vacuum dryer needs to be welded during processing, and there are certain requirements when welding. Different mechanical eq…