Overview:Product descriptionSZG double cone vacuum dryer is a new generation of drying device developed by our factory in combination with the technology of similar domestic products. The double cone vacuum adopts two elastic connection methods of belt and cha…

Product description

SZG double cone vacuum dryer is a new generation of drying device developed by our factory in combination with the technology of similar domestic products. The double cone vacuum adopts two elastic connection methods of belt and chain, so the equipment runs smoothly. The specially designed process fully reflects the good concentricity of the two shafts. The heat medium and vacuum system adopt reliable mechanical seals or rotary joints.

The SZG series double cone rotary vacuum dryer produced by our company is divided into two categories: glass-lined type and stainless steel type according to the material of the inner tank. According to the different nature of the customer's materials, customers can choose according to their needs. In the production and sales of more than ten years, our company has continuously innovated and improved according to the actual needs of customers, overcoming a variety of enamel process difficulties, and has made many breakthroughs in the glass-lined double cone rotary vacuum dryer. It is at the forefront of drying performance and ensuring the purity of materials.

As a professional drying equipment manufacturer, our products are available from high-temperature heat transfer oil as the heat medium, medium-temperature steam and low-temperature hot water. When drying viscous materials, our factory will specially design a "copy board" mechanism for you in the tank or set up a ball or flying knife for high-speed cutting to solve the phenomenon of material unity.

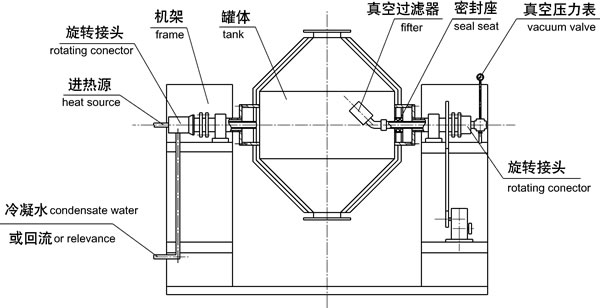

Schematic

Working principle

● The heat energy (such as hot water, low pressure steam or heat transfer oil) is passed into the closed interlayer, and the heat is transferred to the dried material through the inner shell.

● Driven by power, the tank body rotates slowly, and the materials in the tank are continuously mixed, so as to achieve the purpose of intensified drying.

● The material is in a vacuum state, and the vapor pressure drops so that the water (solvent) on the surface of the material reaches a saturated state and evaporates, and is discharged and recovered by the vacuum pump in time. The water (solvent) inside the material continuously infiltrates, evaporates, and discharges to the surface. The three processes are carried out continuously, and the material achieves the purpose of drying in a short time.

Scope of application

It is suitable for the concentration, mixing, drying of powder, granular and fiber in the chemical, pharmaceutical, food and other industries and materials that require low-temperature drying (such as biochemical products, etc.). It is more suitable for easy oxidation, volatile, heat sensitivity, strong irritation, and toxicity. Drying of materials and materials that are not allowed to destroy crystals.

Performance characteristics

● When oil is heated, it adopts automatic constant temperature control, which can dry biochemical products and mineral raw materials, and the temperature can be between 60 and 280 ℃.

● High thermal efficiency, more than 2 times higher than general oven.

● Indirect heating, the material will not be polluted and meet the requirements of "GMP". The maintenance and operation of the equipment are simple and easy to clean.

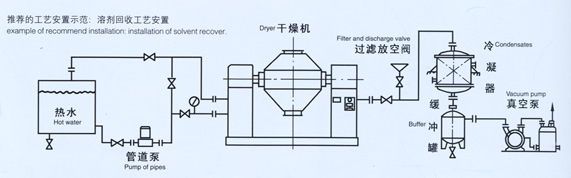

Installation diagram

Recommended process placement demonstration: solvent recovery process placement

Technical specifications

| Name/Specification | 100 | 350 | 500 | 750 | 1000 |

| Tank volume | 100 | 350 | 500 | 750 | 1000 |

| Loading volume (L) | ≤50 | ≤175 | ≤250 | ≤375 | ≤500 |

| Heating area (m2) | 1.16 | 2 | 2.63 | 3.5 | 4.61 |

| Speed (rpm) | 4 - 6 | ||||

| Motor power (kw) | 0.75 | 1.1 | 1.5 | 2 | 3 |

| Floor area length × width (mm) | 2160×800 | 2260×800 | 2350×800 | 2560×1000 | 2860×1300 |

| Rotation height (mm) | 1750 | 2100 | 2250 | 2490 | 2800 |

|

Design pressure in tank (Mpa) |

-0.1-0.15 | ||||

| Jacket design pressure (Mpa) | ≤0.3 | ||||

| Working temperature (oC) | Inside the tank≤85 Jacket≤140 | ||||

| When using a condenser, a vacuum pump, | 2X-15A | 2X-15A | 2X-30A | 2X-30A | 2X-70A |

| Model, power | 2KW | 2KW | 3KW | 3KW | 505KW |

| When the condenser is not used, the vacuum pump, | SK-0.4 | SK-0.8 | SK-0.8 | SK-2.7B | SK-2.7B |

| Model, power | 1.5KW | 2.2KW | 2.2KW | 4KW | 4KW |

| Weight (kg) | 800 | 1100 | 1200 | 1500 | 2800 |

| Name/Specification | 1500 | 2000 | 3500 | 4500 | 5000 |

| Tank volume | 1500 | 2000 | 3500 | 4500 | 5000 |

| Loading volume (L) | ≤750 | ≤1000 | ≤1750 | ≤2250 | ≤2500 |

| Heating area (m2) | 5.58 | 7.5 | 11.2 | 13.1 | 14.1 |

| Speed (rpm) | 4 - 6 | ||||

| Motor power (kw) | 3 | 4 | 5.5 | 7.5 | 11 |

| 占地面积长×宽(mm) | 3060×1300 | 3260×1400 | 3760×1800 | 3960×2000 | 4400×2500 |

| Rotation height (mm) | 2940 | 2990 | 3490 | 4100 | 4200 |

|

Design pressure in tank (Mpa) |

-0.1-0.15 | ||||

| Jacket design pressure (Mpa) | ≤0.3 | ||||

| Operating temperature (oC) | -0.1-0.15 | ||||

| When using a condenser, a vacuum pump, | JZJX300-8 | JZJX300-4 | JZJX600-8 | JZJX600-4 | JZJX300-4 |

| Model, power | 7KW | 9.5KW | 11KW | 20.5KW | 22KW |

| When the condenser is not used, the vacuum pump, | SK-3 | SK-6 | SK-6 | SK-9 | SK-10 |

| Model, power | 5.5KW | 11KW | 11KW | 15KW | 18.5KW |

| Weight (kg) | 3300 | 3600 | 6400 | 7500 | 8600 |

Note: For materials with large changes in volume before and after drying, the loading factor can be appropriately increased or decreased.

1. Drying rate of drying equipment1. The weight lost by the material in unit time and unit area is called drying rate.2. Drying process(1) In…

1. At present, the enamel spray powder in my countrys glass-lined equipment industry is mainly divided into two categories: cold spray (powde…

The new type of rotary flash dryer uses a variety of devices, such as a variety of feeding devices, so that the feeding is continuous and sta…

Centrifugal spray dryer is approvedIn terms of production process and equipment performance, our spray dryer has been highly recognized and p…

Drying equipment is very widely used in industrial testing. Many fields require the use of drying equipment. Similarly, drying equipment also…

The enamel rotary vacuum dryer needs to be welded during processing, and there are certain requirements when welding. Different mechanical eq…