Overview:With the strengthening of the countrys economic strength and the improvement of national environmental protection awareness, the urban sewage treatment industry has developed rapidly, and the output of urban sludge is increasing day by day. The dispos…

With the strengthening of the country's economic strength and the improvement of national environmental protection awareness, the urban sewage treatment industry has developed rapidly, and the output of urban sludge is increasing day by day. The disposal and development and utilization of sludge are increasingly concerned. The sludge of rivers and channels with multiple microorganisms has been neglected for a long time, and it has also brought many problems to urban environmental governance. The sludge dryer developed by Halma can dry the sludge, which is convenient for the production of sludge bio-organic fertilizer. It is the preferred drying equipment for organic fertilizer manufacturers. The drying treatment of sludge makes it possible to treat sludge for agricultural purposes, use as fuel, incineration, and even reduce landfill sites.

Application

Pad dryers have been successfully used in food, chemical, petrochemical, dye, industrial sludge and other fields. The characteristics of heat transfer, cooling and stirring of the equipment make it possible to complete the following unit operations: calcination (low temperature), cooling, drying (solvent recovery), heating (melting), reaction and sterilization. The stirring blade is also a heat transfer surface, which increases the heat transfer area per unit effective volume and shortens the processing time. The heat transfer surface of the wedge-shaped blade has a self-cleaning function. Compression-expansion stirring function makes the material mixed evenly. The material moves in a "piston flow" along the axial direction. In the axial interval, the temperature, humidity, and mixing degree gradient of the material are very small.

● Using thermal oil as the heating medium, the paddle dryer can complete the low-temperature calcination work. For example, calcium sulfate dihydrate (Ca2SO4·2H2O) is calcined and converted into calcium sulfate hemihydrate (Ca2SO4·1/2H2O). Sodium bicarbonate (NaHCO3) is converted into soda ash (Na2CO3) after calcination.

● The cooling medium can be used for cooling, such as water, cooling brine, etc. For example, the paddle-type alkali cooler used in the soda ash industry replaces the old air-cooled soda cooler, which saves energy and exhaust gas treatment equipment, reduces operating costs, and can also be used for titanium dioxide, nickel-iron alloy powder and various powders. Material cooling. The material can be cooled from 1000°C to less than 40°C in a single machine.

● Drying, the most important function of the equipment, does not use hot air, so that solvent recovery, energy consumption, and environmental control are in an ideal state of easy handling. It is especially suitable for the need to recover solvents, flammable and oxidizable heat sensitive materials. It has been widely used in fine chemical, petrochemical and dye industries.

● The uniformity of temperature, humidity, and mixing degree in the axial range makes the equipment used for heating or melting, or for some solid material reactions. It has been successfully used in the compound fertilizer and modified starch industries. The paddle dryer can be used to sterilize food and flour. The large heating area in the unit effective volume can quickly heat the material to the sterilization temperature, avoiding long-term heating and changing the quality of the material.

Features

● The blade dryer has low energy consumption: due to indirect heating, there is no large amount of air to take away the heat, and the outer wall of the dryer is provided with an insulation layer. For slurry materials, only 1.22kg of water vapor is needed to evaporate 1kg of water.

● Low cost of paddle dryer system: the unit effective volume has a huge heat transfer surface, which shortens the processing time and reduces the size of the equipment. This greatly reduces the building area and building space.

● Wide range of processing materials: using different heat media, it can process heat-sensitive materials as well as materials that require high-temperature processing. Commonly used media are: steam, heat transfer oil, hot water, cooling water, etc. It can be operated continuously or intermittently, and can be used in many fields.

● Low environmental pollution: No air is used, and there is little dust material entrainment. The solvent evaporation of the material is very small, which is easy to handle. For contaminated materials or working conditions where solvents need to be recovered, a closed loop can be used.

● Low operating cost: The equipment operates normally, only 1-2 people/day. Low speed mixing and reasonable structure. The amount of wear is small and the maintenance cost is very low.

● Stable operation: Due to the special compression-expansion and stirring effect of the wedge-shaped blade, the material particles are fully in contact with the heat transfer surface. In the axial interval, the temperature, humidity, and mixing degree gradient of the material is small, thereby ensuring the process The stability.

With the strengthening of the country's economic strength and the improvement of national environmental protection awareness, the urban sewage treatment industry has developed rapidly, and the output of urban sludge is increasing day by day. The disposal and development and utilization of sludge are increasingly concerned. The sludge of rivers and channels with multiple microorganisms has been neglected for a long time, and it has also brought many problems to urban environmental governance. The sludge dryer developed by Halma can dry the sludge, which is convenient for the production of sludge bio-organic fertilizer. It is the preferred drying equipment for organic fertilizer manufacturers. The drying treatment of sludge makes it possible to treat sludge for agricultural purposes, use as fuel, incineration, and even reduce landfill sites.

Application

Pad dryers have been successfully used in food, chemical, petrochemical, dye, industrial sludge and other fields. The characteristics of heat transfer, cooling and stirring of the equipment make it possible to complete the following unit operations: calcination (low temperature), cooling, drying (solvent recovery), heating (melting), reaction and sterilization. The stirring blade is also a heat transfer surface, which increases the heat transfer area per unit effective volume and shortens the processing time. The heat transfer surface of the wedge-shaped blade has a self-cleaning function. Compression-expansion stirring function makes the material mixed evenly. The material moves in a "piston flow" along the axial direction. In the axial interval, the temperature, humidity, and mixing degree gradient of the material are very small.

● Using thermal oil as the heating medium, the paddle dryer can complete the low-temperature calcination work. For example, calcium sulfate dihydrate (Ca2SO4·2H2O) is calcined and converted into calcium sulfate hemihydrate (Ca2SO4·1/2H2O). Sodium bicarbonate (NaHCO3) is converted into soda ash (Na2CO3) after calcination.

● The cooling medium can be used for cooling, such as water, cooling brine, etc. For example, the paddle-type alkali cooler used in the soda ash industry replaces the old air-cooled soda cooler, which saves energy and exhaust gas treatment equipment, reduces operating costs, and can also be used for titanium dioxide, nickel-iron alloy powder and various powders. Material cooling. The material can be cooled from 1000°C to less than 40°C in a single machine.

● Drying, the most important function of the equipment, does not use hot air, so that solvent recovery, energy consumption, and environmental control are in an ideal state of easy handling. It is especially suitable for the need to recover solvents, flammable and oxidizable heat sensitive materials. It has been widely used in fine chemical, petrochemical and dye industries.

● The uniformity of temperature, humidity, and mixing degree in the axial range makes the equipment used for heating or melting, or for some solid material reactions. It has been successfully used in the compound fertilizer and modified starch industries. The paddle dryer can be used to sterilize food and flour. The large heating area in the unit effective volume can quickly heat the material to the sterilization temperature, avoiding long-term heating and changing the quality of the material.

Features

● The blade dryer has low energy consumption: due to indirect heating, there is no large amount of air to take away the heat, and the outer wall of the dryer is provided with an insulation layer. For slurry materials, only 1.22kg of water vapor is needed to evaporate 1kg of water.

● Low cost of paddle dryer system: the unit effective volume has a huge heat transfer surface, which shortens the processing time and reduces the size of the equipment. This greatly reduces the building area and building space.

● Wide range of processing materials: using different heat media, it can process heat-sensitive materials as well as materials that require high-temperature processing. Commonly used media are: steam, heat transfer oil, hot water, cooling water, etc. It can be operated continuously or intermittently, and can be used in many fields.

● Low environmental pollution: No air is used, and there is little dust material entrainment. The solvent evaporation of the material is very small, which is easy to handle. For contaminated materials or working conditions where solvents need to be recovered, a closed loop can be used.

● Low operating cost: The equipment operates normally, only 1-2 people/day. Low speed mixing and reasonable structure. The amount of wear is small and the maintenance cost is very low.

● Stable operation: Due to the special compression-expansion and stirring effect of the wedge-shaped blade, the material particles are fully in contact with the heat transfer surface. In the axial interval, the temperature, humidity, and mixing degree gradient of the material is small, thereby ensuring the process The stability.

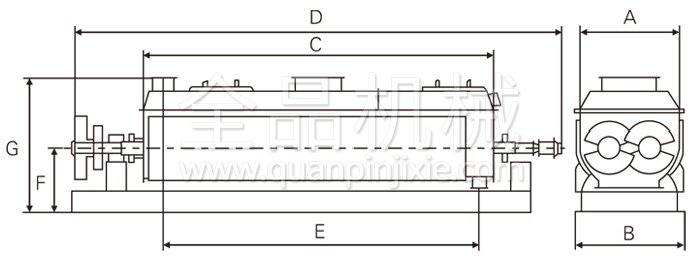

Installation structure diagram

|

Characteristic parameter table

|

||||||||

|

Model number

|

KJG-2.7

|

KJG-9

|

KJG-13

|

KJG-18

|

KJG-24

|

KJG-29

|

KJG-36

|

KJG-41

|

|

Heat transfer area m2

|

2.7

|

9

|

13

|

18

|

24

|

29

|

36

|

41

|

|

Effective volume m3

|

0.06

|

0.32

|

0.59

|

1.09

|

1.53

|

1.85

|

2.42

|

2.8

|

|

Range of rotation r.p.m

|

15-30

|

10-25

|

10-25

|

10-20

|

10-20

|

10-20

|

10-20

|

10-20

|

|

Power kw

|

2.2

|

4.0

|

5.5

|

7.5

|

11

|

11

|

15

|

15

|

|

Body width A mm

|

306

|

584

|

762

|

940

|

1118

|

1118

|

1296

|

1296

|

|

Total width B mm

|

736

|

841

|

1066

|

1320

|

1474

|

1474

|

1676

|

1676

|

|

Body length C mm

|

1956

|

2820

|

3048

|

3328

|

3454

|

4114

|

4115

|

4724

|

|

Total length D mm

|

2972

|

4876

|

5486

|

5918

|

6147

|

6808

|

6960

|

7570

|

|

In and out material distance E mm

|

1752

|

2540

|

2768

|

3048

|

3150

|

3810

|

3810

|

4420

|

|

Center height F mm

|

380

|

380

|

534

|

610

|

762

|

762

|

915

|

915

|

|

Total height G mm

|

762

|

838

|

1092

|

1270

|

1524

|

1524

|

1778

|

1778

|

|

Steam inlet N inch

|

(2)3/4

|

(2)3/4

|

(2) 1

|

(2) 1

|

(2) 1

|

(2) 1

|

(2) 1

|

(2) 1

|

|

Steam outlet 0 inch

|

(2)3/4

|

(2)3/4

|

(2) 1

|

(2) 1

|

(2) 1

|

(2) 1

|

(2) 1

|

(2) 1

|

|

Characteristic parameter table

|

|||||||||

|

Model number

|

KJG-48

|

KJG-52

|

KJG-62

|

KJG-68

|

KJG-73

|

KJG-81

|

KJG-87

|

KJG-95

|

KJG-110

|

|

Heat transfer area m2

|

48

|

52

|

62

|

68

|

73

|

81

|

87

|

95

|

110

|

|

Effective volume m3

|

3.54

|

3.96

|

4.79

|

5.21

|

5.78

|

6.43

|

7.39

|

8.07

|

9.46

|

|

Range of rotation r.p.m

|

10-20

|

10-20

|

10-20

|

10-20

|

5-15

|

5-15

|

5-15

|

5-15

|

5-10

|

|

power kw

|

30

|

30

|

45

|

45

|

55

|

55

|

75

|

75

|

95

|

|

Body width A mm

|

1474

|

1474

|

1651

|

1652

|

1828

|

1828

|

2032

|

2032

|

2210

|

|

Total width B mm

|

1854

|

1854

|

2134

|

2134

|

2286

|

2286

|

2438

|

2438

|

2668

|

|

Body length C mm

|

4724

|

5258

|

5410

|

5842

|

5461

|

6020

|

5537

|

6124

|

6122

|

|

Total length D mm

|

7772

|

8306

|

8865

|

9296

|

9119

|

9678

|

9119

|

9704

|

9880

|

|

In and out material distance E mm

|

4420

|

4954

|

4953

|

5384

|

5004

|

5562

|

5080

|

5664

|

5664

|

|

Center height F mm

|

1066

|

1066

|

1220

|

1220

|

1220

|

1220

|

1220

|

1220

|

1220

|

|

Total height G mm

|

2032

|

2032

|

2362

|

2362

|

2464

|

2464

|

2566

|

2566

|

2668

|

|

Steam inlet N inch

|

(2)11/2

|

(2)11/2

|

(2)11/2

|

(2)11/2

|

(2)11/2

|

(2)11/2

|

(2)2

|

(2)2

|

(2)2

|

|

Steam outlet 0 inch

|

(2)11/2

|

(2)11/2

|

(2)11/2

|

(2)11/2

|

(2)11/2

|

(2)11/2

|

(2)2

|

(2)2

|

(2)2

|

1. Drying rate of drying equipment1. The weight lost by the material in unit time and unit area is called drying rate.2. Drying process(1) In…

1. At present, the enamel spray powder in my countrys glass-lined equipment industry is mainly divided into two categories: cold spray (powde…

The new type of rotary flash dryer uses a variety of devices, such as a variety of feeding devices, so that the feeding is continuous and sta…

Centrifugal spray dryer is approvedIn terms of production process and equipment performance, our spray dryer has been highly recognized and p…

Drying equipment is very widely used in industrial testing. Many fields require the use of drying equipment. Similarly, drying equipment also…

The enamel rotary vacuum dryer needs to be welded during processing, and there are certain requirements when welding. Different mechanical eq…