Overview:Principle:After the air is heated and purified, it is introduced from the bottom by the induced draft fan and passes through the hole plate of the hopper. In the working chamber, fluidization is formed by the action of stirring and negative pressure, …

Principle:

After the air is heated and purified, it is introduced from the bottom by the induced draft fan and passes through the hole plate of the hopper. In the working chamber, fluidization is formed by the action of stirring and negative pressure, the moisture is quickly evaporated and then taken away with the exhaust gas, and the material is quickly dried.

Application:

● Machine-made screw extruded pellets, swing pellets, wet high-speed mixing and granulated pellets.

● Drying of wet granular and powdery materials in the fields of medicine, food, feed, chemical industry, etc.

● Large particles, small lumps, sticky lumps and granular materials.

● Konjac, polyacrylamide and other materials whose volume changes during drying.

Features:

● The fluidized bed has a circular structure to avoid dead ends.

● Stirring is set in the hopper to avoid agglomeration of wet materials and channeling when dry.

● Tipping and unloading is adopted, which is convenient, rapid and thorough, and an automatic feeding and discharging system can also be designed according to requirements.

● Airtight negative pressure operation, the gas is filtered. Easy to operate and easy to clean, it is an ideal equipment that meets the requirements of "GMP".

● Fast drying speed, uniform temperature, the drying time of each batch is generally 20-30 minutes.

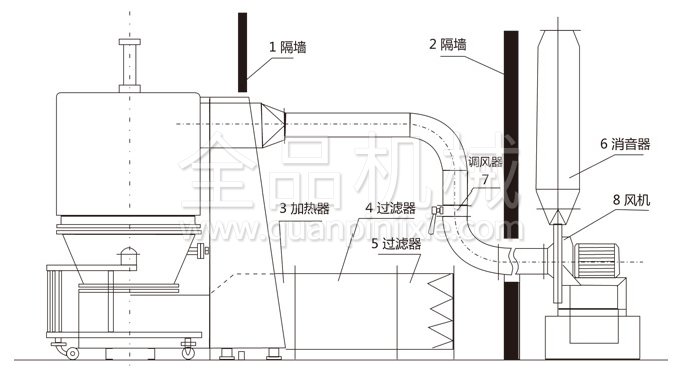

Schematic

Technical specifications

|

Project

|

Unit

|

Model

|

|||||||

|

Feeding

|

kg

|

60

|

100

|

120

|

150

|

200

|

300

|

500

|

|

|

Fan

|

Air volume

|

m3/h

|

2361

|

3488

|

4000

|

4901

|

6032

|

7800

|

10800

|

|

Wind pressure

|

mmH2O

|

594

|

533

|

533

|

679

|

787

|

950

|

950

|

|

|

power

|

kw

|

7.5

|

11

|

15

|

18.5

|

22

|

30

|

45

|

|

|

Stirring power

|

kw

|

0.55

|

0.55

|

0.55

|

0.55

|

0.55

|

1.5

|

2.2

|

|

|

Stirring speed

|

r.p.m

|

11

|

|||||||

|

Steam consumption

|

kg/h

|

141

|

170

|

170

|

240

|

282

|

366

|

451

|

|

|

Operating time

|

min

|

15-30 (Depending on the material situation)

|

|||||||

|

Host height

|

Square

|

mm

|

2750

|

2850

|

2850

|

2900

|

3100

|

3300

|

3650

|

|

Round shape

|

mm

|

2700

|

2900

|

2900

|

2900

|

3100

|

3600

|

3850

|

|

1. Drying rate of drying equipment1. The weight lost by the material in unit time and unit area is called drying rate.2. Drying process(1) In…

1. At present, the enamel spray powder in my countrys glass-lined equipment industry is mainly divided into two categories: cold spray (powde…

The new type of rotary flash dryer uses a variety of devices, such as a variety of feeding devices, so that the feeding is continuous and sta…

Centrifugal spray dryer is approvedIn terms of production process and equipment performance, our spray dryer has been highly recognized and p…

Drying equipment is very widely used in industrial testing. Many fields require the use of drying equipment. Similarly, drying equipment also…

The enamel rotary vacuum dryer needs to be welded during processing, and there are certain requirements when welding. Different mechanical eq…