Overview:DW series multi-layer belt dryer is suitable for large-scale production of difficult-to-dry materials with a low drying rate. The equipment has a compact structure, a small footprint, simple operation, convenient maintenance and stable operation. It c…

DW series multi-layer belt dryer is suitable for large-scale production of difficult-to-dry materials with a low drying rate. The equipment has a compact structure, a small footprint, simple operation, convenient maintenance and stable operation. It can be designed into different hot air circulation drying forms according to the drying characteristics of the material. It is an extension and improvement of the hot air circulation oven and is widely used in metallurgical additives, chemicals, food, packaging and other fields. With the advancement of enterprise technology and the improvement of product technology content, multi-layer belt dryers have the ability to meet large-scale production, diversification, centralized control and continuous production. It has the advantages of high efficiency, energy saving and easy management.

Product description:

DW series belt dryer is a continuous drying equipment for batch production. It is used for drying flakes, strips, and granular materials with good air permeability. It has high moisture content for dehydrated vegetables, catalysts, and Chinese herbal medicine pieces. The material that does not allow high temperature is particularly suitable; this series of dryers have the advantages of fast drying speed, high evaporation strength, and good product quality. For paste-like materials in the form of dehydrated filter cakes, they need to be granulated or made into strips. dry.

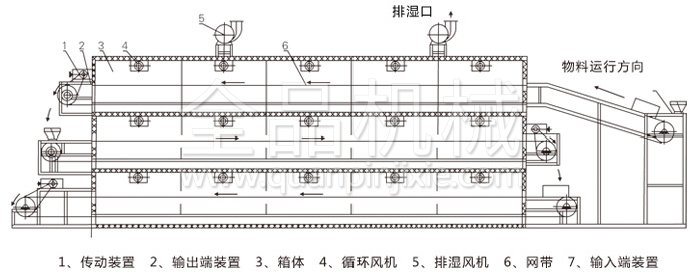

Schematic

| Model | DW3-1.2-8 | DW3-1.2-10 | DW3-1.6-8 | DW3-1.6-10 | DW3-2-8 | DW3-2-8 |

| Number of units | 4×3 | 5×3 | 4×3 | 5×3 | 4×3 | 5×3 |

| Bandwidth (m) | 1.2 | 1.6 | 2 | |||

| Drying section length (m) | 8×3 | 10×3 | 8×3 | 10×3 | 8×3 | 10×3 |

| Spreading thickness (mm) | 10-80 | |||||

| Operating temperature (℃) | 50-140 | |||||

| Steam pressure (Mpa) | 0.2-0.8 | |||||

| Steam consumption (kg/h) | 360-600 | 420-720 | 450-840 | 480-960 | 480-960 | 630-1350 |

| Heat exchange area (m2) | 816 | 1020 | 1056 | 1320 | 1344 | 1680 |

| Dry strength kg water/h | 150-450 | 220-550 | 240-600 | 280-750 | 280-750 | 350-900 |

| Number of fans | 14 | 17 | 14 | 17 | 14 | 17 |

| Total power of internal machine (kw) | 30.8 | 37.4 | 42 | 51 | 56 | 68 |

| Total power of equipment (kw) | 35.3 | 41.9 | 46.5 | 55.5 | 60.5 | 72.5 |

| Dimensions (L×W×H) | 9.77×2.2×4.5 | 11.77×2.2×4.5 | 9.77×2.6×4.7 | 11.77×2.6×4.7 | 9.77×3.06×4.9 | 11.77×3.06×4.9 |

| Total weight (kg) | 4800×3 | 5780×3 | 5400×3 | 6550×3 | 6350×3 | 7800×3 |

Note: The amount of evaporated water shown in the figure depends on the drying temperature of the material, the thickness of the material and the residence time.

1. Drying rate of drying equipment1. The weight lost by the material in unit time and unit area is called drying rate.2. Drying process(1) In…

1. At present, the enamel spray powder in my countrys glass-lined equipment industry is mainly divided into two categories: cold spray (powde…

The new type of rotary flash dryer uses a variety of devices, such as a variety of feeding devices, so that the feeding is continuous and sta…

Centrifugal spray dryer is approvedIn terms of production process and equipment performance, our spray dryer has been highly recognized and p…

Drying equipment is very widely used in industrial testing. Many fields require the use of drying equipment. Similarly, drying equipment also…

The enamel rotary vacuum dryer needs to be welded during processing, and there are certain requirements when welding. Different mechanical eq…