Overview:product descriptionThis unit is a device that can complete drying and granulation at the same time. According to the process requirements, the pressure, flow rate, and size of the nozzle hole of the feed liquid pump can be adjusted to obtain the requi…

product description

This unit is a device that can complete drying and granulation at the same time. According to the process requirements, the pressure, flow rate, and size of the nozzle hole of the feed liquid pump can be adjusted to obtain the required spherical particles in a certain size ratio.

The working process of this unit is that the material liquid is input through the diaphragm pump under high pressure, spraying mist-like droplets, and then descending in parallel with the hot air. Most of the powder particles are collected by the discharge port at the bottom of the tower, and the waste gas and its tiny powder are separated by the cyclone separator. , The exhaust gas is discharged by the exhaust fan, and the powder is collected by the pollinator located at the lower end of the cyclone separator. The outlet of the fan can also be equipped with a secondary dust removal device, and the recovery rate is above 96-98%.

The materials of the tower body, pipes and separators in the contact part of this unit with the materials are all made of SUS304. There is a sufficient moisturizing layer between the inside of the tower and the outer shell. The filling material is ultra-fine glass wool. The tower is equipped with an observation door, sight glass, light source and control instrument, which are controlled and displayed by the electrical control console.

Applications

Pharmaceutical industry: tablets, granules, capsule granules; low-sugar, sugar-free Chinese patent medicine granules; food: cocoa, coffee, milk powder, granular juice, condiments, etc.; other industries: pesticides, feed, fertilizer, pigments, dyes, etc.

Features

1. The drying speed is fast, and the surface area of the material liquid is greatly increased after atomization. In the hot air flow, 95% -98% of the water can be evaporated in an instant, and the time to complete the drying is only ten seconds to tens of seconds, especially Suitable for drying heat sensitive materials.

2. All products are spherical particles with uniform particle size, good fluidity, good solubility, high product purity and good quality.

3. It has a wide range of applications. According to the characteristics of the material, it can be dried with hot air or granulated with cold air, which has strong adaptability to the material.

4. The operation is simple and stable, the control is convenient, and it is easy to realize automatic operation.

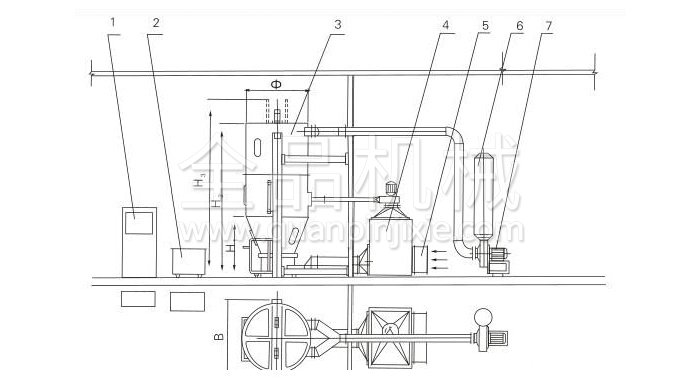

Schematic

1. Control cabinet 2. Infusion trolley 3. Host 4. Heat exchange cabinet 5. Sub-high efficiency filter 6. Muffler 7. Induced draft fan

Technical Parameters

| Item | Unit/model | PGL-3B | PGL-5B | PGL-10B | PGL-20B | PGL-30B | PGL-80B | PGL-120B | |

| Flow extract | min | kg/h | 2 | 4 | 5 | 10 | 20 | 60 | 100 |

| max | kg/h | 4 | 6 | 15 | 30 | 40 | 100 | 140 | |

| Boiling capacity | min | kg/批 | 2 | 6 | 10 | 30 | 60 | 100 | 150 |

| max | kg/批 | 6 | 15 | 30 | 80 | 160 | 250 | 450 | |

| Liquid specific gravity | kg/L | ≤1.30 | |||||||

|

Quantity of raw material container |

L | 26 | 50 | 220 | 420 | 620 | 980 | 1600 | |

| Container diameter | mm | 400 | 550 | 770 | 1000 | 1200 | 1400 | 1600 | |

| Power of induced draft fan | kw | 3.0 | 5.5 | 7.5 | 11 | 15 | 18.5 | 30 | |

| Auxiliary fan power | kw | 0.35 | 0.75 | 0.75 | 1.20 | 2.20 | 2.20 | 4 | |

| steam | Consumption | kg/h | 40 | 70 | 99 | 210 | 300 | 366 | 465 |

| pressure | Mpa | 0.40-0.60 | |||||||

| Electric heating power | kw | 9 | 15 | 21 | 25.5 | 51.5 | 60 | 75 | |

| Compressed air | Consumption | m3/min | 0.5 | 0.8 | 0.8 | 0.9 | 1.1 | 1.3 | 1.8 |

| pressure | Mpa | 0.40-0.60 | |||||||

| Operating temperature | °C | Room temperature -160°C automatic adjustment | |||||||

| Product moisture | % | ≥0.2 | |||||||

| Material recovery rate | % | ≥99 | |||||||

| Equipment noise | dB | <77 | |||||||

| Host size | Φ | mm | 400 | 550 | 770 | 1000 | 1200 | 1400 | 1600 |

| H1 | mm | 940 | 1050 | 1070 | 1220 | 1570 | 1590 | 1690 | |

| H2 | mm | 1900 | 2360 | 2680 | 3150 | 3630 | 4120 | 5050 | |

| H3 | mm | 2050 | 2590 | 3020 | 3600 | 4180 | 4770 | 5800 | |

| B | mm | 740 | 890 | 1110 | 1420 | 1620 | 1820 | 2100 | |

Selection example: It is required that the volume of the processed extract of each batch I=120kg (solid content is 30%), the amount of seeds II=60kg, and the theoretical finished product volume M=mI+mII=120kgx30%+60kg can be derived from I and II =96kg, working time T=120kg/30kg/h=4h, the boiling volume can be found in the technical parameter column as the standard load range, so if two batches are completed per shift, the PGL-30 type is more appropriate.

1. Drying rate of drying equipment1. The weight lost by the material in unit time and unit area is called drying rate.2. Drying process(1) In…

1. At present, the enamel spray powder in my countrys glass-lined equipment industry is mainly divided into two categories: cold spray (powde…

The new type of rotary flash dryer uses a variety of devices, such as a variety of feeding devices, so that the feeding is continuous and sta…

Centrifugal spray dryer is approvedIn terms of production process and equipment performance, our spray dryer has been highly recognized and p…

Drying equipment is very widely used in industrial testing. Many fields require the use of drying equipment. Similarly, drying equipment also…

The enamel rotary vacuum dryer needs to be welded during processing, and there are certain requirements when welding. Different mechanical eq…